STAY TUNED !

Kompressor Bauer Junior-II / B-100 (100 Liter/min ,Germany Made)

Durability, reliability, versatility in application and compact flexibility have made the JUNIOR II a global classic and genuine best seller with more than 100,000 units sold the world over.

Dimensions on a very small scale and sophisticated technology make our most compact mobile breathing air compressor ideal for shipping, as a diving compressor, in respiratory applications, and as a compressor for paintball and sport shooting.

In short, it is a must for anyone looking for absolutely clean and safe breathing air for use in mobile applications.

This quiet and compact unit can be carried easily by a single person and will fit in almost any car boot.

Below is a selection of details and features on the JUNIOR II compressor.

|

|

JUNIOR II compressor blockThe high-pressure compressor block is the “beating heart” of the JUNIOR compressor. Epitomising reliability and having proven its worth in practice for decades, more than 100,000 units have been sold the world over. Plateau-honed cylinders and a perfect fit cooling system enable the compressor block to be used in a wide variety of application ranges. The easily accessible oil filler neck and oil drain make oil changes easy. An oil dipstick is provided so that the oil level can be checked. Long oil change intervals and wear-resistant piston rings reduce running costs to an absolute minimum. |

|

P 21 filter systemWhen used in conjunction with original BAUER filter cartridges, the P 21 filter system with integrated oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 140 m³ of air can be treated. ¹ If the units are maintained and installed correctly as described in the operating instructions or user manual and if the concentration of CO2 in the intake air does not exceed the values specified in the applicable standard for breathing air. |

|

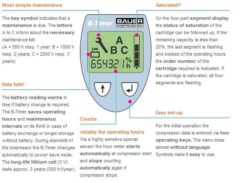

B-TIMER filter cartridge monitoringThe operating hours and the current level of cartridge saturation are displayed on the unique B-TIMER mini-computer. The B-TIMER flashes when a cartridge change is due. At the same time, the purchase order of the filter cartridge required is shown on the display. This ensures that the very best use is made of the filter’s capacity at all times. |

|

Filling DeviceThe filling device comprises a flexible “UNIMAM” high-pressure filling hose and filling valve complete with final pressure gauge. The final pressure gauge makes it easy to read off the filling pressure. It is protected against damage by a durable rubber jacket. |

|

|

Filling hoseHigh-quality UNIMAM high-pressure filling hoses made from food-safe and long-life hose material make for flexible and safe handling. Swivel hose connections enable the filling valve to be connected to the breathing air cylinder quickly, easily and safely. |

|

GS markThe well-known GS mark which comes as standard with the JUNIOR II certifies that the compressor has been tested for safety and meets the exacting requirements of the German Equipment and Product Safety Act. Conformity and compliance with all DIN standards is assured. |

Compact-Line Junior

JUNIOR II compressor, 90 – 330 bar, 100 l/min, high-pressure compressor for compressing air and breathing ai.

Type

|

Effective

|

Drive |

Net

|

DimensionsL x B x H |

|

| l/min | Motor | KW | approx. kg | cm | |

| JuniorII-B | 100 | Robin/Sabaru 4-stroke petrol engine | 4 | 44 | 78 x 34 x 42 |

| JuniorII-E | 100 | Three-phase motor, 400 V, 50 Hz2 | 2.2 | 46 | 66 x 36 x 42 |

| JuniorII-W | 100 | Alternating current motor 230 V, 50 Hz2 | 2.2 | 46 | 66 x 39 x 42 |

¹ Measured with cylinder filling from 0 to 200 bar, ±5%

² Option of different voltage/frequency available

| Weight | 60000 g |

|---|